Why Iron On Patches Are Ideal for Corporate Branding

How Iron On Patches Reinforce Brand Consistency Across Teams

Iron on patches help keep things looking consistent throughout different departments, across various locations, and among all team members since they reproduce the same logos and color schemes every time. Hand stitched embroidery just isn't as reliable because there's always some variation from one batch to another, but when we apply patches using heat, the designs stay exactly the same. When everyone looks the part, customers start recognizing the brand more easily. Employees essentially turn into mobile representations of the company, showing up looking professional during meetings and other business encounters. Companies operating in multiple locations find these patches particularly useful for maintaining brand consistency without having to spend extra money on customizing uniforms region by region.

Cost, Speed, and Scalability Advantages of Iron On Patches for Uniform Programs

Apparel industry reports from last year suggest that iron on patches can cut down corporate branding expenses somewhere around 60 to maybe even 70 percent when compared with traditional embroidery methods. The best part? No need for those fancy sewers anymore. Just slap them on in about a minute or so per shirt instead of waiting forever while someone stitches each piece for over fifteen minutes. Want to scale up uniforms quickly? Patches arrive at your door within three to five business days, which means companies don't have to wait weeks for bulk orders like they do with embroidery shops. Take one bank recently, they had to get 500 hybrid workers dressed up in their new look overnight. Thanks to these stickers, everyone got their gear in just two days flat without anyone going around looking half naked during meetings.

Preparing Fabrics and Garments for Reliable Iron On Patch Adhesion

Identifying Compatible Materials: Cotton, Polyester, and Blends

Cotton and polyester fabrics work great for iron-on patches because they can handle the heat without issues. Cotton-polyester blends are pretty good too, offering something in between (Textile Industry Council 2023). Stay away from those tricky synthetics though - nylon, rayon, and especially vinyl tend to melt easily when exposed to regular iron temps around 370-400 degrees Fahrenheit. Leather is another problem child since it conducts heat unevenly and might end up with unsightly marks after applying patches. Before grabbing your iron, take a quick peek at what the garment label says about heat sensitivity.

Pre-Treatment Essentials: Washing, Drying, and Surface Inspection

When washing clothes for best results, stick to regular laundry detergent and skip the fabric softener stuff completely. This helps get rid of those sizing chemicals and leftover gunk that actually makes things stick together worse later on. Make sure everything is totally dry before moving forward, whether using a dryer or hanging them up somewhere warm. Moisture hiding anywhere will mess up the bonding process for sure. Take time to check every part of the fabric surfaces too. Grab a good quality lint roller and go over everything to pick up any little bits of fluff, stray threads, or creases that might be there. The smoother and cleaner the material is, the better the heat will spread across it during application. Most people find their finished products hold up really well through at least twenty five washes or so when they follow these steps properly.

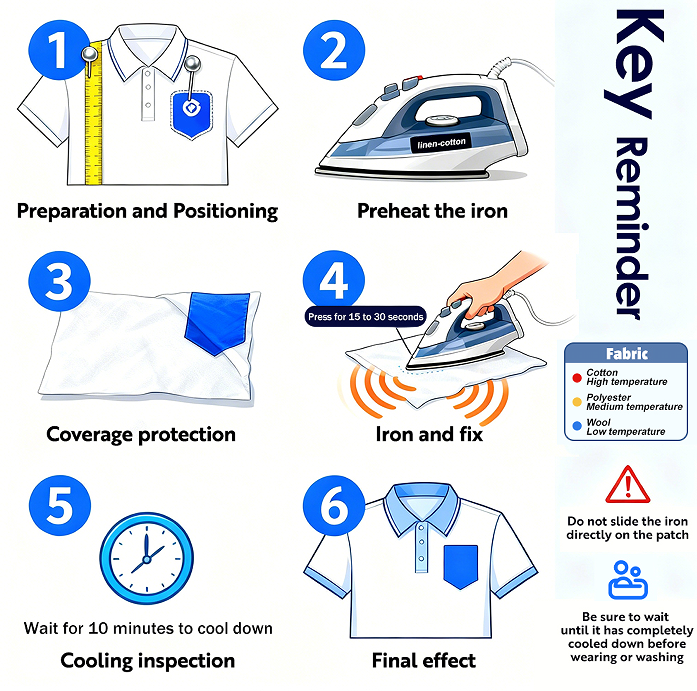

Step by Step Iron On Patch Application for Professional Results

Precise Placement Guidelines for Logos on Shirts, Jackets, and Vests

To keep branding looking good across all apparel, position patches right in the middle at the top of polo shirts, about 2 to 3 inches down from where the collar sits. On jackets, put them on the left side of the chest area, somewhere between the seam line and the pocket space. Vest backs should have patches dead center too. Fabric markers work great as temporary guides since they show up well even when someone is wearing the garment. When working on team uniforms specifically, it's important to take measurements starting from either the shoulder seams or collar points to make sure everything lines up properly. Getting within 1/8 inch difference makes a big difference visually speaking. Don't skip testing out patch placement using a template first though. This step can save a lot of headaches later on if things get misaligned after heating.

Optimal Heat, Time, and Pressure Settings by Fabric Type

Apply patches using fabric-specific settings to prevent scorching or weak bonds:

- Cotton: 320°F, 30 seconds with firm pressure and a pressing cloth

- Polyester: 280°F, 15 seconds with light pressure to avoid melting

- Blends: 300°F, 20 seconds with moderate pressure

After heating, allow full cooling before testing the bond. Gently lift each corner; if peeling occurs, reapply heat in 10-second intervals. Proper execution ensures patches withstand industrial laundering without lifting.

Maintaining Durability and Appearance of Iron On Patches in Daily Use

Post Application Cooling, Bond Testing, and Quality Control

After applying the patch, give it at least ten minutes to cool down without touching it so the glue can really grab hold. Check out those corners with your fingernails too. If any part starts to lift up, just apply some heat again for about half a minute while pressing firmly. Look closely for air pockets, creases, or spaces between the patch and surface. The patch needs to sit completely flat against whatever it's going on. Taking these extra steps might seem tedious but trust me, doing this right now saves headaches later when walking around all day wearing whatever has been patched.

Washing, Drying, and Storage Best Practices to Extend Patch Lifespan

To keep those patches looking good for longer, turn clothes inside out before washing them in cold water using the gentle cycle. Stay away from bleach and fabric softener since they can really mess with the adhesive holding everything together. When it comes to drying, air drying works best. If absolutely necessary to use the dryer, stick to low heat settings below 120 degrees Fahrenheit. For storage, lay items flat or hang them somewhere safe. Never fold right over the patched area as this tends to cause damage over time. Stick with these simple care tips and most iron-on patches should last through at least 25 washes without fading or losing their shape around the edges.