Understanding the Iron On Patch Application Process

What Is the Iron On Patch Application Process?

Iron on patches have this special sticky back made from something called thermoplastic polymer that actually sticks to clothes when heated between around 320 degrees Fahrenheit to about 400 degrees Fahrenheit. What makes these patches so convenient is they eliminate the need for sewing needles altogether, which works great for fixing holes or adding designs to tough fabrics such as jeans and regular cotton stuff. When heated, the glue part gets all melted, mixes into the fabric threads, then hardens again once cooled down, forming what feels like a pretty strong bond most of the time.

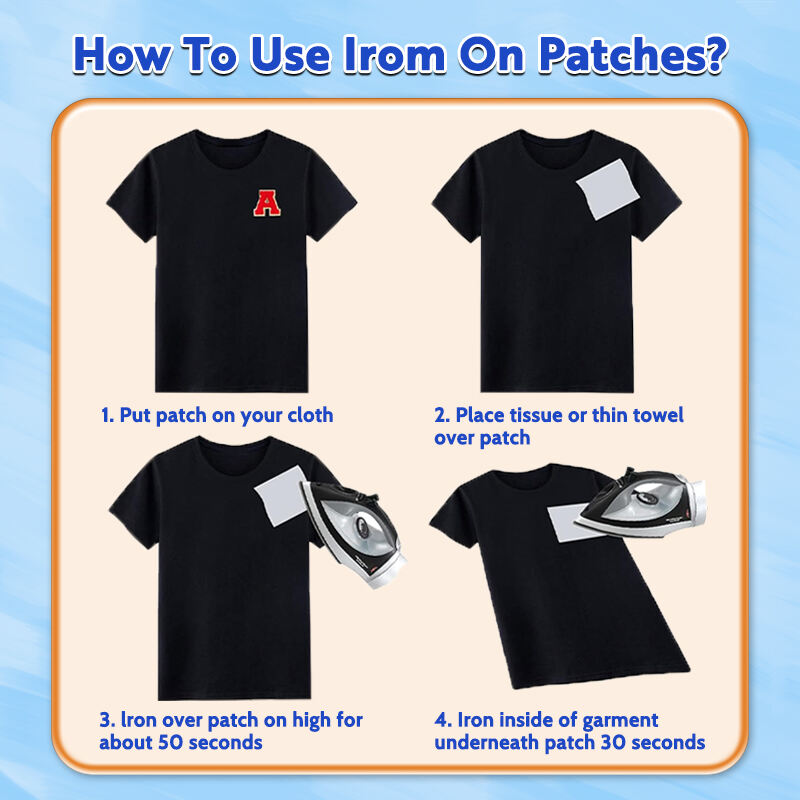

Step by Step Instructions for Applying Iron-On Patches

- Prep the Fabric: Wash and dry the garment to remove residues, then lay it flat on a heat-resistant surface and smooth out wrinkles.

- Position the Patch: Place the patch adhesive-side down in the desired location and cover it with parchment paper.

- Heat Application: Set the iron to 350°F (no steam) and press firmly for 30–45 seconds using even, circular motions to ensure full contact.

- Reinforce: Flip the fabric and apply heat to the reverse side for an additional 20–30 seconds to strengthen the bond.

- Cool and Test: Allow the patch to cool completely for at least 10 minutes before checking adhesion. Gently lift edges with a fingernail; if lifting occurs, reapply heat briefly with protective paper.

How to Iron On Patches Safely and Effectively

Putting down a sheet of parchment paper acts as insurance against scorch marks while helping distribute heat more evenly across the surface. When pressing, keep steady hand pressure throughout the process since patchy contact will create those annoying weak areas we all want to avoid. With delicate materials such as polyester, it's best to dial back the heat setting to around 300 degrees Fahrenheit and only let them sit under the iron for about 15 to 20 seconds maximum. Before starting though, give the fabric a good preheat session to dry out any lingering moisture. This step makes a surprising difference in how well everything sticks together in the end.

Common Mistakes to Avoid When Applying Iron On Patches

- Moving the iron during application, which can shift the patch and create misalignment.

- Using high heat on delicate fabrics such as silk, nylon, or polyester blends, risking melting or scorch marks.

- Skipping preheating, which reduces adhesion strength by up to 40% due to trapped moisture and wrinkles.

- Testing the patch too soon after heating, compromising bond integrity before the adhesive fully sets.

Essential Tools and Materials for Applying Iron On Patches

Tools Needed: Iron, Parchment Paper, and Heat Resistant Surface

A successful application requires three essentials:

- A standard household iron set to 350°F (177°C), without steam

- Parchment paper or a thin cotton cloth to protect the patch and fabric from direct heat

- A stable, heat-resistant surface such as an ironing board or silicone mat

The iron’s flat soleplate ensures uniform pressure, while parchment paper prevents scorching and allows controlled heat transfer—especially important for embroidered patches or textured fabrics.

Materials Required for a Successful Iron On Patch Application

You’ll also need:

- Iron-on patches with intact adhesive backing (inspect for damage or peeling edges)

- Natural fiber garments made of cotton, denim, or canvas for optimal results

- Rubbing alcohol or mild detergent to clean the application area before patching

Pre-washed fabrics minimize post-application shrinkage, and patches with reinforced borders resist fraying and delamination over time.

Why Using Parchment Paper or a Protective Cover Is Crucial

Parchment paper serves as kind of heat shield, letting warmth get through evenly while keeping things from getting too hot for fabrics to handle. If folks skip this step, those synthetic fabrics tend to melt away, and all that fancy embroidery thread just burns right off when exposed directly. Once heated up, giving the patch some time to cool down completely before touching it makes a big difference. Around a minute or so works best for most people, since this cooling period lets the glue really set in properly. Missing this part often means patches coming loose after just a few washes.

Preparing Fabric and Selecting Suitable Materials

How to Properly Prepare Fabric Before Applying Iron On Patches

Begin by washing and drying the garment to remove oils, dirt, and finishing chemicals that hinder adhesion. Iron it at a medium setting to eliminate wrinkles and ensure a smooth surface. Avoid starch or fabric softeners, as they leave residues that interfere with bonding, especially on cotton and denim.

Pre-Treating Cotton and Denim for Optimal Adhesion

Pre-washing removes factory coatings that weaken adhesive performance. For denim, lightly sand the target area to increase surface texture and promote better grip. Finish by using a lint roller to clear dust and loose fibers from both fabric and patch site.

Best Fabrics for Iron On Patches: Cotton and Denim Explained

Cotton and denim are ideal due to their high heat tolerance (up to 350°F) and tightly woven structures. Cotton absorbs heat evenly, while denim provides a durable base for strong adhesion. In controlled testing, these fabrics retain up to 85% of patch integrity after 50 wash cycles.

Challenges with Polyester, Nylon, and Silk: Heat Sensitivity and Adhesion Issues

When working with polyester or nylon fabric, remember these materials start melting at temperatures over 300 degrees Fahrenheit. That means it's important to set your iron to a lower temperature setting and never forget to place a pressing cloth between the fabric and the hot surface. Silk requires even more care since it reacts badly to high heat and can easily get scorched. A good trick learned through trial and error is placing a heat resistant silicone sheet underneath the silk to protect it during pressing. And for anyone dealing with synthetic materials or other delicate textiles, there's one golden rule worth remembering: always do a quick test first on some hidden area of the garment, maybe near a seam nobody will see, just to make sure everything works out before committing to the final press job.

Best Practices for Durable and Long Lasting Iron On Patches

Professional results depend on precise temperature control, consistent pressure, and proper cooling. These factors directly influence how well the patch withstands wear and washing, with correctly applied patches lasting through 20–30 laundry cycles according to textile care studies.

Optimal Temperature Settings: 350°F and No Steam

Set your iron to 350°F (177°C)—the sweet spot for activating thermoplastic adhesives without damaging most natural fibers. Avoid steam, as moisture interferes with bonding and increases the risk of edge lifting. If possible, verify iron accuracy with an infrared thermometer.

Applying Even Pressure and Allowing Sufficient Cooling Time

Apply firm, steady pressure for 30–45 seconds, moving in small circles to distribute heat uniformly. Immediately after heating, place a heavy book or weight over the patch during cooling to maintain contact as the adhesive hardens. Premature handling weakens the bond—wait 10–15 minutes before use.

The Importance of Preheating Fabric Before Patch Application

Pre-iron the garment for about 60 seconds to remove moisture and flatten fibers. This prepares a clean, dry surface for maximum adhesive contact, particularly beneficial for thick or textured fabrics like denim. Skipping this step significantly compromises bond strength.

Debunking the Steam Debate: To Steam or Not to Steam?

While some sources claim steam helps patches conform to curved areas, empirical tests show it reduces bond strength by 25–35%. Moisture disrupts the adhesive layer, leading to early failure. For curved surfaces like hats, consider using a heat press with a silicone mold instead of relying on steam.

Ensuring Full Adhesion: Inspecting for Edge Lifting After Cooling

Once cooled, check the patch edges by running a credit card along the perimeter. If any section lifts, reapply heat for 15 seconds using parchment paper as a shield. This secondary treatment improves wash resistance by 18%, based on textile engineering data, and ensures lasting hold.

FAQ

Can all types of fabric handle iron-on patches?

No, not all fabrics are suitable for iron-on patches. Cotton and denim are ideal due to their durability and heat tolerance. Delicate fabrics like silk, nylon, and polyester require careful handling and lower heat settings.

Why is parchment paper necessary in the application?

Parchment paper protects the fabric from direct heat, prevents scorch marks, and helps distribute heat evenly, ensuring a strong bond between the patch and the fabric.

What's the purpose of preheating fabric before applying patches?

Preheating helps remove moisture from the fabric, ensuring a clean, dry surface for optimal adhesion of the patch.

How can I test if the patch is securely applied?

Once cooled, gently lift the edges with a fingernail. If any part lifts, reapply heat with parchment paper to reinforce the bond.