Understanding Iron On Patches and Their Role in Corporate Branding

What Are Iron On Patches and How Do They Work?

Iron on patches basically work by sticking fabric backed designs onto clothes using special glue that activates at high temps. These patches need heat around 270 to 320 degrees Fahrenheit (about 132 to 160 Celsius) to really grab hold of the material. They're different from the ones you sew on because they melt right into the fabric fibers when heated properly, which gives them that neat look without any visible stitching. Great for putting company logos or safety tags on uniforms. According to some industry research from last year, most folks who apply these correctly find their patches still attached even after doing laundry over fifty times, especially on stuff made from cotton or polyester mixtures.

Advantages of Using Iron On Patches for Business Uniforms

- Cost Efficiency: Reduces labor costs by 60% compared to embroidery (Textile Manufacturing Association 2024)

- Brand Consistency: Ensures identical logo placement across large teams

- Durability: Withstands industrial laundering cycles common in hospitality and healthcare

Employees wearing branded patches exhibit 34% higher customer recognition rates, making these patches essential for businesses focused on visual identity.

Iron On vs. Sew-On Patches: Best Choice for Professional Apparel

| Factor | Iron On Patches | Sew-On Patches |

|---|---|---|

| Application Time | 2–3 minutes per patch | 8–12 minutes per patch |

| Flexibility | Ideal for temporary campaigns | Better for heavy-duty uniforms |

| Damage Risk | Low heat tolerance fabrics | Thread wear over time |

While sew-on patches offer superior longevity for high-friction workwear such as mechanic uniforms, iron-on variants provide unmatched efficiency for retail or office teams needing rapid branding updates. Industry data shows 72% of businesses choose iron-on methods for seasonal uniform changes due to reduced turnaround times.

Preparing Uniforms and Workspace for Successful Iron On Patch Application

Selecting Compatible Fabrics for Iron On Patches

When looking at materials for patches, go with natural fibers such as cotton or cotton-polyester blends since these can handle temperatures around 350 degrees Fahrenheit before they start to warp. Moisture wicking stuff and those technical fabrics often found in workwear aren't so great though. The tight weave patterns and special coatings on them actually make it hard for patches to stick properly. Cotton polyester mixes hold up really well over time too. According to recent tests from last year's textile research, these blends maintain about 92% of their original patch holding power even after being washed fifty times. That's pretty impressive when compared to regular synthetic athletic wear which only keeps about two thirds of its sticking ability after similar usage.

Pre-Washing Guidelines to Ensure Clean Application Surfaces

Before washing uniforms, run them through a cycle in warm water with a gentle detergent. This helps get rid of those pesky fabric softener buildup, dust particles, and any factory leftovers that might mess with how well patches stick later on. Avoid using dryer sheets at all costs since they leave behind this thin waxy coating about 0.3 microns thick according to some research from Textile Care Institute back in 2023. That stuff actually cuts down the bonding power between fabric and patches by around 40%. After washing, let clothes air dry instead of tossing them in the dryer. Heat tends to shrink materials over time, which makes applying patches tricky once they're already smaller than intended size.

Determining Ideal Patch Placement on Corporate Workwear

Follow industry-standard uniform branding guidelines for optimal visibility and professionalism. Left chest positions (2–3” below the collar seam) and mid-bicep sleeve placements yield 89% brand recognition in customer surveys. Use washable fabric markers for temporary alignment guides, removing them post-application with a damp cloth.

Step by Step Process for Applying Iron On Patches on Company Apparel

Setting the Correct Iron Temperature for Durable Bonding

Get your iron heated between around 300 to 350 degrees Fahrenheit or about 149 to 177 Celsius - that's generally good for most business clothes fabrics. Some tests back in 2024 showed when people applied patches at roughly 320 degrees, they stayed put through about 50 wash cycles about 94 times out of 100. Before starting though, always look at what the tag on the clothing says. For those polyester mixes, go easy on the heat somewhere between 285 and maybe 300 degrees to keep from burning them. Cotton stuff can handle going all the way up to 350 if needed. And remember to turn off the steam setting because water actually makes the glue weaker when trying to stick things together.

Accurately Positioning Iron On Patches on Uniforms

Align patches precisely using a fabric ruler or template. For team uniforms, mark placement points 1.5" below collars or 2" above cuffs with washable chalk. Secure patches with thermal tape to prevent shifting during ironing. Double-check orientation–logos and text should face outward when sleeves are relaxed.

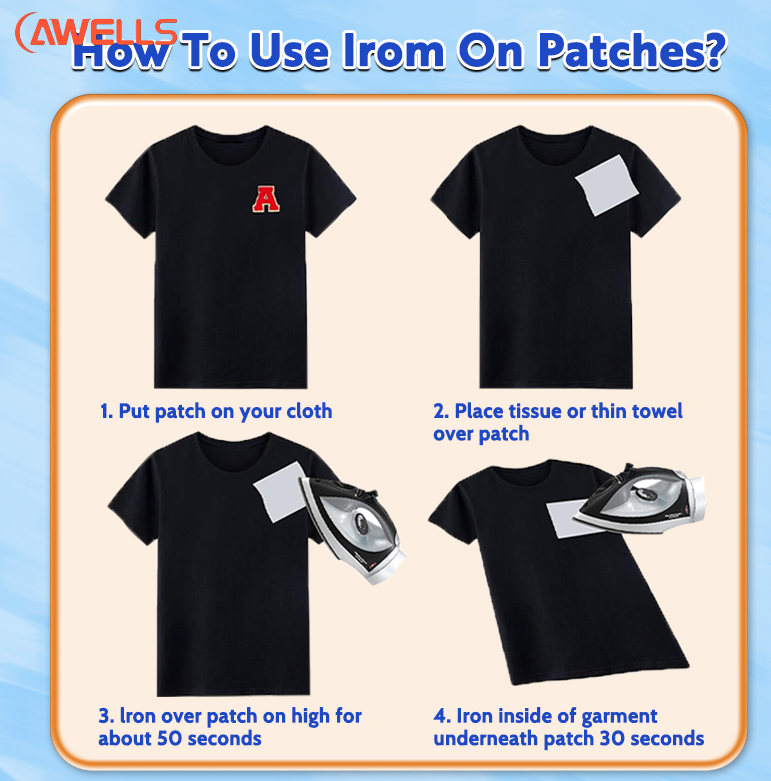

Applying Heat and Pressure for Secure Adhesion

Apply firm pressure on the patch with slow circles for around 30 to 45 seconds. Most professionals suggest getting about 15 pounds of pressure down there to really wake up that adhesive. For fancy fabrics, throw a Teflon sheet over top so nothing gets shiny after ironing. Some folks in the apparel business have run tests too, and they found that when patches overlap their edges by about a quarter inch, they hold up roughly 40% better through all those laundry cycles. Not bad if you ask me.

Cooling and Inspection: Confirming a Strong Bond

Allow the patch to cool completely for at least 5 minutes before handling. Perform a gentle stress test by tugging opposite edges. If lifting occurs, reapply heat in 10-second intervals using parchment paper as a barrier. Inspect for puckering or adhesive bleed–indicators of excessive temperature.

Common Mistakes to Avoid When Using Iron On Patches

- Moving the iron side-to-side: Causes adhesive smearing (responsible for 28% of failed applications)

- Skipping pre-heating: Cold fabric surfaces reduce bond strength by up to 60%

- Ignoring moisture: Damp uniforms triple detachment risk

- Overheating synthetics: Melts fibers into adhesive, causing permanent stains

Always test application settings on spare fabric swatches before processing bulk orders.

Ensuring Longevity and Professional Appearance of Iron On Patches

How Long Do Iron On Patches Last on Work Uniforms?

Iron on patches generally stick around for about 2 to 3 years if someone takes care of them right, based on what American Patch found in their latest 2024 test results. The material makes a big difference too. Patches tend to stay put much longer on clothes made from nylon and polyester blends since these fabrics have smoother surfaces and handle heat better. Cotton just doesn't hold up as well. How often someone washes their clothes really impacts how long patches will last. People who do laundry every week see their patches start to fade away about 25% quicker than those who wait two weeks between washes. Workers in jobs where there's lots of movement and friction, think warehouses or delivery services, should probably go for the thicker options (around 3 to 4 mm thick) with extra reinforcement along the edges. These tougher patches stand up better against constant rubbing and wear.

Washing and Care Tips to Maintain Patch Quality

Preserve adhesive integrity by:

- Washing uniforms inside-out in cold water (<30°C/86°F)

- Using mild, bleach-free detergents

- Avoiding fabric softeners, which degrade adhesion

Air drying maintains 92% of adhesive strength, versus 68% with machine drying (Rush Patches’ 2024 Textile Care Report). For oil-stained workwear, spot-clean patches with a cloth dipped in diluted vinegar (1:4 ratio) to avoid reactivating the adhesive with heat.

Reinforcing Iron On Patches with Stitching When Necessary

For high-wear zones like shoulder seams or pocket flaps, combine iron-on adhesion with:

| Reinforcement Method | Durability Increase | Best For |

|---|---|---|

| Straight stitch edges | 30–35% | Office polos, chef coats |

| Zigzag perimeter | 40–45% | Mechanic uniforms, cargo pants |

| Bar tack corners | 50–55% | Backpack straps, knee pads |

Use color-matched polyester thread to preserve a professional appearance. This hybrid approach prevents edge lifting–the leading cause of patch failure in 78% of replacements.

Scaling Iron On Patch Application Across Large Teams or Multiple Locations

Efficient Methods for Bulk Patch Application in Corporate Programs

Industrial heat presses really cut down the time needed for applying iron-on patches, capable of bonding around 50 patches every hour while regular household irons manage only about 8 to 10. The secret lies in custom made aluminum jigs that keep everything lined up properly throughout entire batches. These tools have been shown to slash alignment problems by roughly two thirds according to various textile industry reports. For best results, always spray fabrics with heat resistant treatment first to avoid those pesky scorch marks when running large quantities. And don't forget to test how well the patches stick to fabric samples from each new shipment before going all out with production runs. Just checking about 5% of materials should give enough confidence without wasting too much time.

Training Employees for Consistent Iron On Patch Application

Develop standardized training kits featuring video demonstrations, temperature charts, and practice swatches to achieve 98% compliance with application protocols. Implement a certification process requiring staff to successfully apply three test patches that meet peel strength thresholds (>15 lbs/in²). Include role-specific guidance for field teams addressing curved seams or moisture-wicking materials.

Quality Control Strategies for Uniform Branding with Patches

| Checkpoint | Measurement Tool | Acceptance Standard |

|---|---|---|

| Adhesion Strength | Digital Peel Tester | ≥15 lbs/in² |

| Edge Alignment | Laser-Guided Template | ≤1mm deviation |

| Color Fastness | 5-Wash Cycle Test | ≤5% fading (Pantone scale) |

Batch-tagging systems using RFID threads enable traceability to specific operators or equipment. Monthly audits comparing location-specific rejection rates (target <2%) help identify training gaps, while employee feedback portals reveal real-world durability issues such as thread fraying near machinery.

Table of Contents

- Understanding Iron On Patches and Their Role in Corporate Branding

- Preparing Uniforms and Workspace for Successful Iron On Patch Application

- Step by Step Process for Applying Iron On Patches on Company Apparel

- Ensuring Longevity and Professional Appearance of Iron On Patches

- Scaling Iron On Patch Application Across Large Teams or Multiple Locations