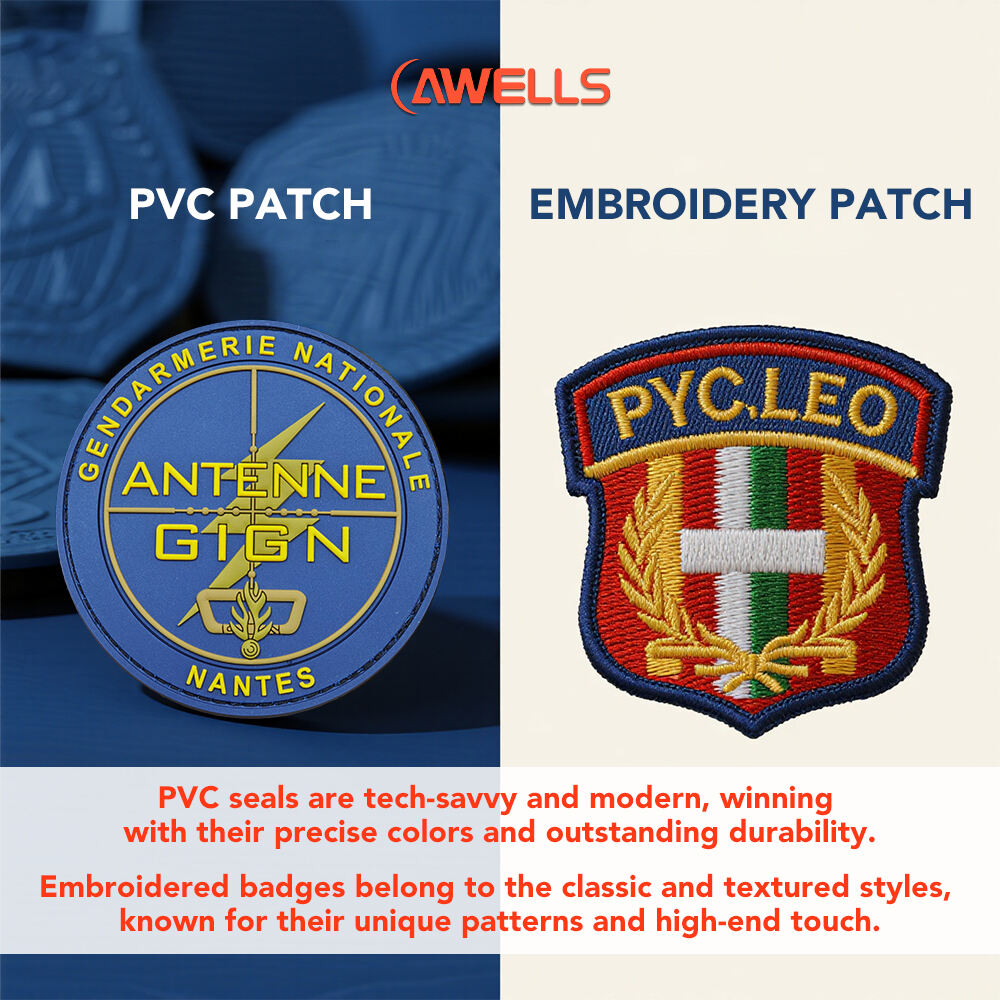

Material and Construction: Core Differences Between PVC and Embroidered Patches

What makes PVC patches so tough? Well, they're made from polyvinyl chloride, basically a type of plastic that can be molded into shape using injection techniques. When manufacturers use this approach, they get some pretty cool results. Edges come out clean and precise, colors blend smoothly across gradients, and those raised 3D details stay crisp even after years of wear. Since PVC is a synthetic material, it doesn't fray at the seams or fade in sunlight like other fabrics might. That's why many companies choose PVC when designing intricate logos that need some pop off the surface. Think about those big name brands with elaborate emblems on their products – chances are good they're using PVC patches to maintain that professional look without compromising on quality.

Embroidered patches are constructed from layered thread stitched onto fabric backings like twill or felt. While they offer a classic textured appearance, stitch spacing limits ultra-fine details—text smaller than 0.2†often becomes illegible due to thread density constraints.

Key Distinctions in Material, Texture, and Tactile Feel

- PVC: Smooth, rubbery surface with consistent thickness (1.5-3mm standard)

- Embroidery: Rich texture, fabric texture varies depending on needle type (satin and chain)

- Flexibility: PVC will not crack when bent at extreme temperatures (-40 ° F to 200 ° F), while embroidery patches may warp if backed with hard materials

Visual Appearance: Color Vibrancy, Design Sharpness, and Dimensionality

PVC’s dye-infused production achieves 94% color accuracy against Pantone standards, surpassing embroidered patches, which average 78% due to thread limitations. For designs with gradients or shadows, PVC enables seamless transitions via layered molding. Embroidery can only suggest depth through stitch direction, limiting realism and detail fidelity.

Durability and Performance: Long Term Use in Real-World Conditions

Durability of PVC Patches in Extreme Conditions and Frequent Handling

PVC patches perform well in harsh environments due to their chemically resistant and wear-resistant polymer structure. They can withstand temperatures ranging from -40 ° F to 200 ° F and can withstand three times more processing cycles than embroidery patches without cracking or discoloration.

Lifespan and Wear Resistance of Embroidered Patches Under Daily Use

Embroidery patches usually last for 2-3 years under daily wear and tear before visible wear and tear appears. Simulation tests show that after approximately 5000 friction cycles, the thread begins to loosen, and within 12 months, there is pilling of the backing. The edge stitching of the high contact area first deteriorates.

Weather Resistance: UV Exposure, Moisture, and Abrasion Tolerance

PVC outperforms embroidery in environmental resilience:

| Factor | PVC | Embroidered |

|---|---|---|

| UV Resistance | 500+ hours stable | Fades after 200 hrs |

| Water Exposure | Fully waterproof | Risk of mold/mildew |

| Abrasion | Minimal surface wear | Threads snap under friction |

Recent durability analysis confirms PVC retains 92% color vibrancy after accelerated weather testing, compared to 58% for embroidered patches. This makes PVC particularly suitable for outdoor gear and safety equipment exposed to prolonged sun and moisture.

Aesthetic Impact and Brand Image: Aligning Patch Style with Identity

Professional Perception of Embroidered Patches in Corporate and Formal Branding

Embroidered patches bring a professional look thanks to their fabric texture and subtle matte appearance. The clean lines created by the stitching really work well for sectors like banking, legal services, and hotel management where classic styles matter most. According to some industry research published last year, around three out of four companies see these embroidered designs as trustworthy markers for institutions. This connection is strongest when we talk about items like tailored jackets, employee wear, and other dressy accoutrements that need to convey authority without shouting it.

Modern, Bold Aesthetics of PVC Patch Designs for Youth and Outdoor Brands

PVC patches create really eye-catching, almost 3D effects because they're made from molded plastic. That's why so many brands targeting young people, fitness enthusiasts, and outdoor gear lovers go for them when they want something that stands out visually. The shiny surfaces, bright colors that pop right off the material, plus options like gradient transitions, metallic looks, and even custom cutouts make these patches super noticeable on things like backpacks, athletic wear, and all sorts of promotional stuff. They basically give brands a way to break away from boring old fabric designs and stand apart in crowded markets.

Balancing Visual Appeal with Brand Positioning Across Industries

| Industry | Preferred Patch Type | Brand Image Alignment |

|---|---|---|

| Hospitality | Embroidered | Classic, upscale, discreet |

| Tech Startups | PVC | Innovative, bold, energetic |

| Law Firms | Embroidered | Authoritative, professional |

Brand positioning depends on the target audience and industry expectations. Outdoor companies prioritize the durability and eye-catching design of PVC, while service-oriented industries favor understated and elegant embroidery. Matching material properties with brand value ensures identity consistency without sacrificing functional performance.

Design Flexibility and Customization Options for PVC and Embroidered Patches

Complexity Handling: Fine Details in Logos and Typography

When it comes to getting those really detailed designs on patches, PVC material stands out because injection molding can hit pretty impressive specs around 0.2 to 0.5 millimeters. That level of detail matters a lot when creating things like company logos with those fancy serif fonts or complicated technical drawings that need to stay clear and legible. Embroidery just doesn't cut it for these kinds of jobs though. The threads have to be at least 2 mm apart from each other, which means anything too fine gets lost in the process. Sharp corners get softened up and those little letters we spend so much time designing? They tend to disappear altogether under all that stitching.

Limitations of Stitch Count vs. Mold Precision in PVC Patch Production

When there are too many stitches in a design, say over 15,000 of them, embroidered patches tend to lose some of their sharpness because all those threads start building up. This is where PVC comes in handy since it doesn't have this problem at all thanks to how it's made with molds. Embroidery does have one advantage though it lets designers create nice subtle changes in tone by layering different threads together. With PVC, colors stay pretty much solid like Pantone blocks. The thing about making complex molds for PVC patches does drive up the price initially. A 5 color 3D PVC patch will typically cost around 40% more right off the bat compared to just a regular flat version. But what people often forget is that these higher priced options actually last much longer when put through tough conditions, which makes them worth considering for certain projects.

Cost, Production, and Strategic Selection for B2B Branding Needs

Choosing between PVC and embroidered patches involves balancing upfront investment, volume efficiency, and brand goals. PVC requires mold creation ($150–$500), but per-unit costs drop significantly at scale—bulk orders (1,000+) average $0.85–$1.50 each. Embroidered patches have no tooling fees but higher per-piece material costs ($1.20–$2.75), making them economical only for small runs (<500 units).

Looking at what's happening in the industry these days, about 73 percent of companies go with PVC when they need something tough enough for outside stuff or heavy duty equipment. Embroidery still wins out though for business wear where people want something more understated. The time it takes to get products ready varies quite a bit too. For PVC items, we're talking around three to five weeks because of all the mold work and waiting for things to set properly. Embroidered patches usually come through faster, shipping within ten to fourteen days most of the time. When it comes down to picking one over the other, it really depends on what kind of brand image someone wants to project. Younger companies and those in tech tend to love how eye catching PVC looks with its three dimensional pop effect. Traditional businesses stick with embroidery because it just feels right for them, reinforcing their long standing reputation for quality workmanship and old school values.

FAQ Section

What are the key differences between PVC and embroidered patches?

PVC patches are made from a type of plastic, offering clean edges, vibrant colors, and durability against wear and sunlight. They don't fray or fade like embroidered patches, which are made from layered threads stitched onto fabric, offering a more textured look.

Which patch type is more suitable for outdoor use?

PVC patches are more suitable for outdoor use as they withstand harsh conditions better than embroidered patches. They are fully waterproof and maintain color vibrancy even after prolonged sun exposure, making them ideal for outdoor gear.

How do PVC and embroidered patches affect brand image?

PVC patches offer a modern and bold appearance, preferred by brands targeting youth and outdoor enthusiasts. Embroidered patches provide a classic and professional look, suitable for sectors like banking and legal services.

Which patch type offers better design flexibility?

PVC patches offer better design flexibility, allowing for detailed designs, non-standard shapes, and vibrant color options. Embroidered patches have limitations in achieving fine details due to thread density constraints.

What factors should I consider when choosing between PVC and embroidered patches for branding?

When choosing between PVC and embroidered patches, consider your brand's image, the intended use of the patches, durability needs, and budgeting for production. PVC is ideal for intricate designs and durability, while embroidered patches align with a classic and professional look.

Table of Contents

- Material and Construction: Core Differences Between PVC and Embroidered Patches

- Durability and Performance: Long Term Use in Real-World Conditions

- Aesthetic Impact and Brand Image: Aligning Patch Style with Identity

- Design Flexibility and Customization Options for PVC and Embroidered Patches

- Cost, Production, and Strategic Selection for B2B Branding Needs

-

FAQ Section

- What are the key differences between PVC and embroidered patches?

- Which patch type is more suitable for outdoor use?

- How do PVC and embroidered patches affect brand image?

- Which patch type offers better design flexibility?

- What factors should I consider when choosing between PVC and embroidered patches for branding?