Why Choose PVC Patches for Brand Uniforms?

Tactile Brand Consistency and Visual Impact

PVC patches offer something special when it comes to keeping brands looking consistent across all their materials. The injection molding process basically copies logos and designs so accurately that most people can't tell there's anything but the original artwork on display. These patches hold up way better than embroidery options too. They keep those clean lines and true Pantone colors even after going through hundreds of industrial washes, which matters a lot for folks working in hotels, security services, and hospitals where uniforms need regular cleaning. What makes these really stand out is the 3D embossing technique. When fingers run over those raised parts, it creates this physical connection with the brand. Some research suggests this could boost brand recognition around 47%, though we should probably take that number with a grain of salt since neuromarketing studies often get a bit dramatic. Either way, these textured patches turn everyday work clothes into mobile advertisements, making sure no one looks out of place in company gear.

Superior Durability for High-Use Uniform Environments

PVC patches hold up against harsh conditions that would wear down most other types of emblems. They maintain their shape and strength after going through over 200 industrial washing cycles according to tests from Textile Testing Authority back in 2023. Made from waterproof polymer material, these patches stand up to UV light damage, chemicals, and general wear and tear. Firefighters, soldiers, and workers who spend time outdoors find them especially useful when dealing with tough environmental challenges. Regular woven patches tend to come apart at the edges or just fall off completely, but PVC patches are molded as one piece so they don't unravel no matter how much rubbing occurs on backpack straps or anywhere else where there's constant contact. The durability factor means companies save money in the long run too. Studies show around a 60-65% reduction in replacement costs when switching from traditional embroidery methods. For organizations needing reliable high visibility markings on uniforms, this makes PVC patches a smart choice that pays off over time.

Key PVC Patch Customization Options

Design Flexibility: Logos, Shapes, and Brand-Aligned Aesthetics

PVC patches really open up all sorts of creative possibilities for designers. When it comes to making logos, injection molding can pick up those tiny details right down to about half a millimeter in line thickness. That's way better than what embroidery can manage these days. Plus, this method lets brands create custom shapes that match their existing designs perfectly. The cool thing is that even after going through over 100 industrial laundry cycles, geometric patterns stay crisp and clear. Think about things like animal mascots or outlines of products that need to look good on uniforms worn by big teams or workforces. These designs keep their sharpness and recognition value throughout all that washing, so companies maintain their brand image consistently across entire fleets of uniforms without worrying about the patches wearing out too quickly.

Color Accuracy, 3D Embossing, and Dimensional Effects

Matching colors to Pantone standards keeps batches looking consistent across production runs, which matters a lot when maintaining brand identities. With advanced molding methods, manufacturers can add depth to designs by creating elevation changes around 3 millimeters thick. This turns ordinary flat logos into something customers can actually feel, making the brand experience more memorable. Screen printed items just don't hold up against UV exposure like these 3D effects do. Another benefit comes from those recessed sections that allow for gentle shading effects. Military applications really need this feature since their insignias must meet strict contrast requirements (about 50 times difference between light and dark areas) so they remain visible even in poor lighting conditions.

| Visual Enhancement | Function | Brand Impact |

|---|---|---|

| 3D Embossing | Creates raised surfaces | 62% higher recall (Neuroscience Institute 2023) |

| Gradient Effects | Smooth color transitions | Luxury perception 38% |

| Metallic Finishes | Reflective accents | Premium association 45% |

PVC Patch vs. Alternatives: When PVC Is the Optimal Choice

Teams that need gear to last through tough conditions will find PVC patches beat regular embroidered or woven stuff hands down. Embroidery works fine for simple logos on jackets, but PVC lasts way longer in real world situations. We've seen them hold up three times better against wear and tear, rain, and sun damage. That matters a lot for folks in the military, rescue operations, or anyone working outdoors day after day. What sets PVC apart is how it can create those cool 3D effects and realistic color shifts that just aren't possible with threads. The details get pretty sharp too, around half a millimeter in some cases. Sure, making molds for small runs costs extra upfront compared to fabric options, but most companies save money in the long run because they don't have to replace patches so often. Go with PVC if what you need includes stuff like heavy duty applications, shiny metal looks, angled edges, or water resistance where colors might otherwise run and look unprofessional.

Attachment Methods and Uniform Material Compatibility

Sew-On, Heat Seal, and Hook-and-Loop: Pros, Cons, and Best Use Cases

Picking the right way to attach a PVC patch means finding something that works well with both the fabric type and how it will be used. Sew on patches stick around the longest because they get stitched directly onto the material. These are great choices when dealing with rough wear situations such as military style clothing or heavy duty work clothes where losing a patch just won't cut it. The downside though? Stitching takes time and effort, plus there's always a chance that the process might damage those special waterproof layers found on some performance fabrics. Not everyone wants to deal with all that hassle sometimes.

Heat-seal adhesives offer rapid installation on smooth synthetic fabrics like polyester or nylon, but struggle with textured materials (e.g., canvas) and degrade above 300°F (ASTM D751). Hook-and-loop systems provide repositioning flexibility for seasonal uniforms or multi-garment use, though they add 1.5–3mm thickness and may snag in machinery-heavy environments.

| Method | Best For | Material Limitations |

|---|---|---|

| Sew-On | Fire-resistant uniforms, heavy-duty gear | Stretchy knits, delicate silks |

| Heat Seal | Polyester polos, nylon jackets | Wool, textured cotton, silicone-coated fabrics |

| Hook-and-Loop | Interchangeable logos, outer layers | Low-profile formalwear, fine-knit sweaters |

Prioritize fabric compatibility testing before full production: a leading textile lab study found 23% of heat-seal failures occurred on chemically treated cotton blends.

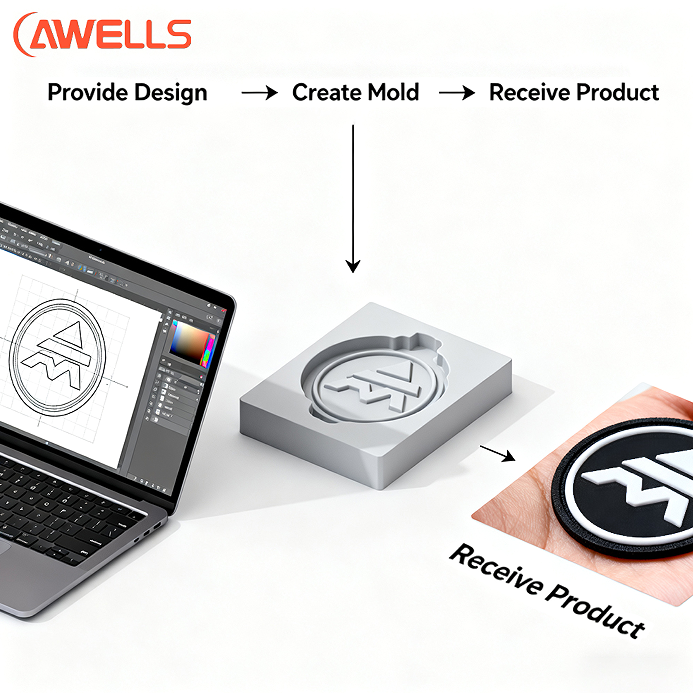

The PVC Patch Production Workflow: From Concept to Delivery

Mold Creation, Silicone Casting, Curing, and Quality Control

When making PVC patches from digital designs, professional manufacturers follow a pretty standard industrial approach. The whole thing starts with those fancy CNC engraved metal molds that basically turn brand logos and artwork into exact shapes and sizes. Then comes the liquid PVC stuff, which is mixed in a specific 4 parts resin to 1 part plasticizer ratio before being poured into silicone molds. For complicated designs, color pigments get added gradually in different layers. Once the molds are filled, they go through heat treatment between around 220 to 280 degrees Celsius. This heating stage is really important because it makes sure the patches won't leak water, stand up to sunlight exposure, and have strong molecular bonds throughout. After taking the patches out of the molds, there's another step where automated cutting tools trim away any excess material to get that clean finished look customers expect.

Each batch undergoes rigorous quality control—including tensile strength tests and colorfastness verification under calibrated lighting. Industry reports indicate strict manufacturers achieve <0.5% defect rates through triple-check protocols before applying backings like Velcro® or heat-activated adhesives. This end-to-end workflow enables delivery of uniform-compliant patches in 2–3 weeks for standard orders.